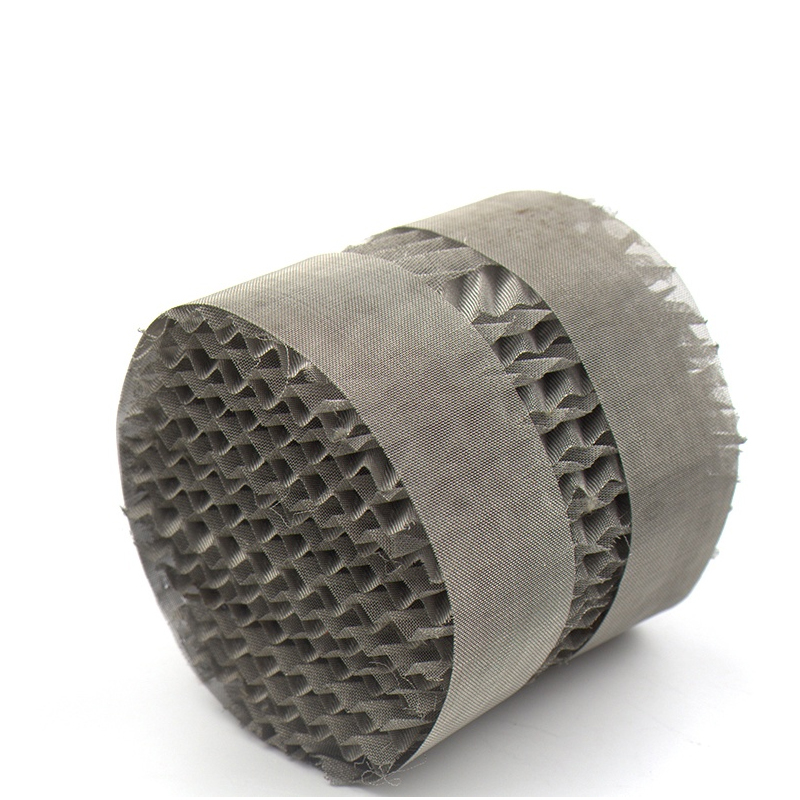

I-Metal Wire Gauze Packing For For Distillation Column

Ukusetshenziswa kwe-Metal Mesh Corrugated Packing

1. Ukulungisa i-organic halide.

2. Ukulungisa nokumunca ezinye izingxube ezonakalisayo, ezilawulwa nakanjani ekwehleni kwengcindezi kanye nenombolo yepuleti le-theoretic.

3. Isetshenziswa kweminye imibhoshongo equkethe isamba esikhulu semithombo yemvelo esetshenziselwa ukumunca i-nitric acid ne-sulfuric acid egxilile, kanye nokuhlanza umoya ezitshalweni zamakhemikhali.

4. Ukusebenza ngaphansi kwezimo ze-vacuum ngaphansi kwengcindezi ephelele engu-100pa.

5. Isetshenziswa ekushiseni nasekususeni ukushisa, noma njengendlela yokuthwala i-catalyst.

I-MMCP ingaba izinhlobonhlobo zezinto, njenge-carbon steel, insimbi engagqwali 304, 304 L, 410, 316, 316 L, njll. ongakhetha kuzo.

Ukucaciswa Kwezobuchwepheshe Kwe-Metal Mesh Corrugated Packing

| Imodeli | Ingxenye engenalutho | Ubukhulu besiqephu mm | Isisindo senqwaba | Ukuphakama kweCrest (mm) | Ibanga lengilazi mm | ukwehla kwengcindezi Mpa/m | Isici sokupakisha M/s.(Kg/m³)0.5 | Ithiyori yenombolo yepuleti Nt/(1/m) |

| 100Y | 90 | 2.5±0.5 | 220-250 | 30 | 50 | 250-300 | 3.5 | 1 |

| 125Y | 90 | 2.5±0.5 | 370 | 23 | 42 | 280-300 | 3 | 1.5-1.8 |

| 160Y | 86 | 2.2±0.2 | 384 | 17 | 34 | 250-300 | 2.8-3.0 | 1.8-2 |

| 250Y | 82 | 1.4±0.2 | 450 | 13 | 22 | 80 | 2.5 | 2-3 |

| 350Y | 80 | 1.2±0.2 | 490 | 9 | 15 | 80 | 2 | 3.5-4 |

| 450Y | 76 | 1±0.2 | 552 | 6 | 11 | 80 | 1.5-2 | 4-5 |

| 550Y(X) | 74 | 0.8±0.2 | 620 | 5 | 10 | 80 | 1.0-1.3 | 6-7 |

| 700Y(X) | 72 | 0.8±0.2 | 650 | 4.5 | 8 | 80 | 1.2-1.4 | 5-6 |

Ukupakisha Nokuthumela

| Iphakheji | Ibhokisi lebhokisi, isikhwama seJumbo, ikesi lezinkuni | |||||

| Isitsha | 20GP | 40GP | 40HQ | Ukuhleleka okuvamile | I-oda elincane | I-oda lesampula |

| Ubuningi | 25 CBM | 54 CBM | 68 CBM | <25 CBM | 1 CBM | < 5 ama-pcs |

| Isikhathi sokuthumela | izinsuku ezingu-7 | izinsuku ezingu-14 | izinsuku ezingu-20 | 7-10Izinsuku | 3 izinsuku | Isitoko |

| Amazwana | Ukwenza ngokwezifiso kuvunyelwe. | |||||