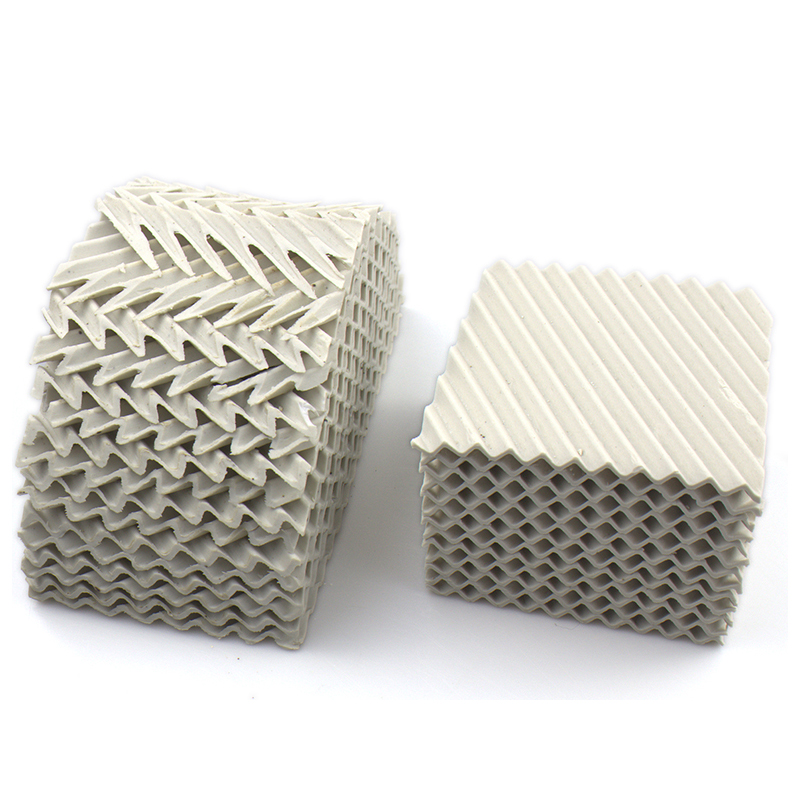

I-Ceramic Structured Tower Packing

Imikhiqizo Isingeniso seI-Ceramic Structure Packing

Ngenxa yesakhiwo esiyingqayizivele se-ceramic, ukusebenza okuhle kwe-hydrophilic, ubuso bayo bungenza ifilimu elincane kakhulu eliwuketshezi lokunyakaziswa komoya okunyakazayo kanye namashaneli ahlukumezayo angakhuthaza umoya kodwa angayeki ukufanisa umoya wokugcwalisa insimbi ungenza ukupakishwa kwe-ceramic, nokumelana kwayo nokugqwala, ukusebenza okuphezulu kokumelana nokushisa kwe-filler yensimbi akukwazi ukuqhathaniswa. Isakhiwo esingaphezulu sinendawo enhle yokumanzisa, singasheshisa ukugeleza koketshezi, kwenze ukupakisha ukubambezeleka kwevolumu yoketshezi kube buncane. Ukunciphisa amathuba okushisa ngokweqile, ukuhlanganisa, nokupheka. Lo mkhiqizo wenziwe ngekhwalithi ephezulu yamakhemikhali e-porcelain yobumba ukucubungula impahla eluhlaza futhi ube, ukumelana nokushisa okuphezulu nokucindezela okuphezulu, ukuqina okuhle kwamakhemikhali namandla aphezulu, uyisithwali esifanelekile sokusekela izinhlobo ezihlukahlukene zama-catalysts.

Chemical Analysis ofI-Ceramic Structure Packing

| Ukwakheka | Inani |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| I-CaO | ≤1.0% |

| I-Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Okunye | 2% |

Impahla Engokomzimba Ye-CeramicUkupakisha Okuhlelekile

| Inkomba | Inani |

| Amandla adonsela phansi athile(g/cm3) | 2.5 |

| Ukumuncwa kwamanzi (wt%) | ≤0.5 |

| Ukumelana ne-Acid (wt%) | ≥99.5 |

| Ukulahlekelwa ekushiseni (wt%) | ≤5.0 |

| Ubukhulu. izinga lokushisa lokusebenza.(℃) | 800 |

| Amandla e-Crush (Mpa) | ≥130 |

| Ubulukhuni bukaMoh(Isikali) | ≥7 |

Ukucaciswa Kwezobuchwepheshe Kwe-CeramicUkupakisha Okuhlelekile

| Ukucaciswa. | Indawo ethile (m2/m3) | Ukuminyana ngobuningi (kg/m3) | Isilinganiso esingenalutho (%) | Obl. i-angle | Ukwehla kwengcindezi (mm Hg/m) | Theo. ipuleti (m-1) | Ububanzi be-Hydraulic (mm) | Umthamo woketshezi (m3/m2h) | Ubukhulu. isici m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |